Imagine that you and your friends are ASIC engineers and you come up with a revolutionary idea for a semiconductor chip which could potentially change our life. You finally agree to start a company and start the ASIC development. But how will you manufacture the silicon wafers? do you need to own a semiconductor foundry?

The answer is not anymore, because since the 80’s semiconductor companies started using the fabless model.

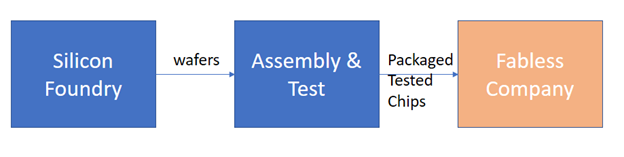

A fabless company is a company that does not own a semiconductor foundry. The term ‘fab’ stands for fabrication, hence, ‘fabless’ indicating that the company does not take any part in the fabrication of the product but instead only participates in the designing and marketing aspects of the semiconductor chips. In the scenario mentioned above, you will be credited for designing and developing as well as responsible for marketing the product, but you do not have to worry about manufacturing it as you will have signed a deal to outsource the fabrication to a third-party manufacturing plant or foundry. The Fabless model has proved to be successful and gave birth to many new semiconductor companies.

How did semiconductor fabless companies come about?

Before the 1980s, vertical integration was the common trend in semiconductor companies which would design, develop, fabricate, and then test and market the products all on their own using their own resources and talent. As time went on, smaller companies began to increase in number on the back of private equity funding and engineers began to design, develop, and present ideas for new semiconductors companies that were specific for certain solutions. Being relatively small companies and startups, they did not, however, have the resources needed to manufacture them. The larger IDMs or Integrated Device Manufacturers, on the other hand, had an excess of production capacity, which led to them beginning to manufacture semiconductors for the smaller players. And thus, the advent of fabless companies was marked in history. Some of these firms included the likes of Xilinx and Altera, as well as Lattice Semiconductor. However, since these companies produced and manufactured their own microprocessors and semiconductors as well, they took priority and manufacturing for fabless companies that were purchasing their surfaces often took place in the downtime. The change arose from Taiwan when TSMC (1987) began a manufacturing plant that was solely dedicated to manufacturing semiconductors for fabless companies and did have any intrinsic product fabrication (e.g.Pure-Play Foundry). Gradually, more and more companies started to lay foundation for manufacturing only firms including the likes of Qualcomm, Broadcom and Marvell.

Advantages of Fabless Model

The reason why semiconductor companies have very own semiconductor fab so that they can develop their semiconductor chips from the start to the finish is that it gives the company a greater degree of control. But the fact of the matter is that it may put the company at more of a disadvantage than it may cause them benefit, which is why they then turn to a fabless business strategy for their business.

A semiconductor fab owned and run by the company itself will require significant contributions in terms of capital, staff, and resource investment, as you would need adequate space, infrastructure, relevant equipment, skilled employees, and storage facilities to supplement the manufacturing process, not to mention the costs associated with the material and skill needed, waste disposal, and routine maintenance. If a company wanted to avoid these high capital and resource investments, turning to a fabless model would essentially solve their strife, as it is a cost-effective alternative that allows them to share the existing manufacturing facilities of a third party which fit their requirements perfectly.

The importance of Fabless Companies in the Semiconductor Industry

The reason why the fabless business model has been adopted so largely and gleefully by some of the major players in the semiconductor industry is because of the utter convenience and potential for growth it brings. With a business strategy where fabless companies can outsource the manufacturing of the semiconductor chips, the fabless companies can instead focus on and focus their time, efforts and resources to develop new ideas, invest in research, and improve their marketing strategies to drive their sales. It also allows them to maintain variability in production volume, efficiency, and velocity without feeling and overburden on their staff and resources.

Companies using the Fabless Business Model Today

Companies such as Qualcomm, Broadcom, AMD, NVIDIA, Xilinx, Marvell and MediaTek are some of the major names in the fabless company realm in terms of the number of sales made and the total revenue generated. The products of these fabless companies have been availed by a number of market leading corporations today including the likes of Apple, DELL, and Samsung- only to name a few. These companies consider fabless manufacturing to be a major part of their IC development strategy as it allows them to keep up with the demand and maintain consistency across their products. The use of the fabless business model has been significantly prevalent in the semiconductor industry since the year 1987 and the trend only seems to be on the rise ever since.

Do We Need a New Model

ASIC design at 14nm/16nm geometry node and below requires much higher design cost in terms of EDA tools and maskset. This NRE cost has reached a level that is not affordable by new startup companies and this has literally reduced the number of new design start. Will this new barrier force engineers to come up with a new business model? Probably yes.